centrifuge nozzle|non perforated basket centrifuge diagram : company Discharge nozzles are constructed of TC. This is an extremely hard material that has a high level of resistance to wear. It's important to replace TC nozzles before they are worn thru. Suggested Repair: None, but inspect the discharge . Notre gamme de bois en pin traité autoclave classe 4 est disponible dans une variété de sections pour répondre à tous vos besoins (bastaings, planches, chevrons, poteaux, etc.).

{plog:ftitle_list}

This service guide provides detailed information on the Delta-XL 8" and Delta-XL 10" sterilizers, .

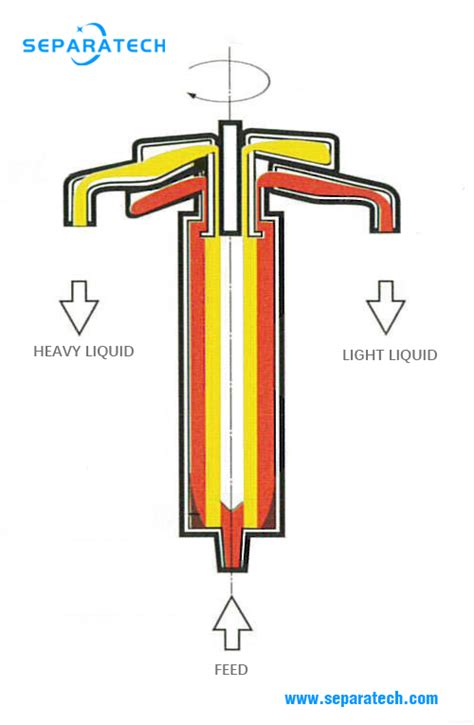

Nozzle separators are continuously operating disk centrifuges. They are built as centrifugal .

operating speed by the distributor. Flottweg nozzle separators are available as 2-phase and 3-phase separators. The 2-phase nozzle separator separates large solid particles directly in the centrifugal field. Finer solids are separated as they flow through the disc pack. The solid particles collect in the bowl’s outer solids chambers.No other Disc Nozzle Centrifuge on the market can compare, feature to feature. FQC-800 • FQC-800T • FQC-800E • FQC-950 • FQC-950T • FQC-950E. DESIGN FEATURES. Heavy Duty construction minimizes vibration and ensures .

Discharge nozzles are constructed of TC. This is an extremely hard material that has a high level of resistance to wear. It's important to replace TC nozzles before they are worn thru. Suggested Repair: None, but inspect the discharge .Nozzle separator is continuously operating disc centrifuge, for concentrating solids and clarifying liquids. Concentrated solids phase is discharged continuously through nozzles. Nozzle separators are built as centrifugal clarifiers and separators. they are more solids-orientated than self-cleaning separators. When they are configured to .

The Flottweg nozzle separator. Energy-saving, maintenance-optimized and powerful . Our nozzle separators are ideally suited for the extraction of wet starch. Advantages and info Nozzle Separator. Decanter. C-Series; X-Series; Z-Series; OSE .31CG is the largest centrifuge with peripheral nozzles for these industries. Applications The FEQX 520S is specifically designed for separation of dis-tiller’s, and fodder yeast as well as other fermentation broths. Separation of particles with sizes down to 0.5 µm is possible.Fluid-Quip has combined many maintenance-friendly features with proven separation technology to design a Disc Nozzle Centrifuge that operates with reliable efficiency and minimum downtime. No other Disc Nozzle Centrifuge on the market can compare, feature to feature. Disc Nozzle Centrifuges can be tailored to each unique operation: Primary .The Nozzle bowl separator is most often used for classification of solids according to size, dewatering and washing of solids, and for clarification of liquids containing relatively high concentrations of solids. It can also be used for 3 phase applications where two liquid phases and a solids phase need to be separated in one step.

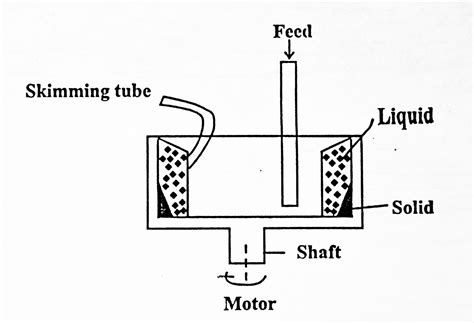

This type of centrifuge removes solid matter from liquid feed from the plates. A centrifugal pump creates a pressure to discharge the clear liquid from the centrifuge.The solid is extracted through nozzles continuously, [1] as shown in Figure 2 [clarification needed].The quantity of concentrate depends on speed of bowl rotation, number of nozzles per centrifuge, radius of the nozzle’s .

The Merco starch separator is a nozzle centrifuge designed to continuously discharge solids, specially developed for the starch industry. The starch centrifuge is equipped with a motor, a self-cleaning strainer for the feed, speed and vibration sensors, oil temperature sensors for the spindle bearings and the motor winding, a hydraulic power unit for the lifting hoist, a set of special tools .Alfa Laval SVSX-210B Stainless Steel Disc Nozzle Centrifuge 21220-02. used. Manufacturer: Alfa-Laval Used Alfa Laval SVSX-210B Stainless Steel Disc Nozzle Centrifuge Manufacturer: Alfa Laval Model: SVSX-210B-74 Serial: 2902357 Material of bowl: stainless steel Tachometer: 710-750 rpm Revolution counter: 11.6.3.2.3 The nozzle separator. The disc-stack centrifuge with continuous solids discharge is called a nozzle discharge machine. The special nozzles mounted in the periphery of the bowl allow for continuous operation with a liquid–liquid–solid feed, separating this mixture into two relatively clean liquid streams and a thick solids suspension.

Solids-discharging nozzle centrifuge for the biotechnological industries BTUX 305 The key to success in bridging the gap from the laboratory to commercial production is a pilot plant that delivers results that will be relevant when moving into full-scale produc-tion. Scaling-up involves compromises that often cannot be

520B-31CG is a nozzle centrifuge optimised for chemical and mining processing featuring a system for recirculation of separated solids. Applications Thanks to its solids recirculation system, the CHQX 520B is ideal for concentration and classification of solid particles.MBPX separator systems. The MBPX is a mobile, easily installed plug-and-play separator system for microbiological applications such as algae, yeast and bacteria. . The FESX and FEQX nozzle bowl separators are designed for industrial fermentation applications and are available in many different sizes and configurations, each one designed and .CHSX 520B - Large capacity nozzle centrifuge Alfa Laval separator centrifuges for the chemical and mining industries are available in many different sizes and configura-tions, each one designed and adapted for dealing with the widely varying separation tasks required. The CHSX 520B-31CG is a nozzle centrifuge optimised for chemical and min-The basic principle behind a disc stack centrifuge is the separation of different components in a mixture based on their density difference. This is achieved by spinning a bowl containing the mixture at high speeds, which generates a .

The CH-38 GOF is a nozzle centrifuge designed for continu-ous discharge of solids. It is used for classification of solids according to size, dewatering and washing of solids, and for clarification of liquids containing relatively high concentrations of solids. The machine is Alfa Laval’s largest nozzle centrifuge for the maize starch industry. Flottweg nozzle separators are used for the continuous separation of solids from liquids and ensure highly efficient clarification or separation. Find out mo.For solids up to 10 vol. %, any GEA Pharma separator can be equipped with the highVol clarifier bowl variant. flexicon nozzle separator The GEA flexicon nozzle bowl answers the needs of many manufacturers for a centrifuge that can handle higher solid contents – up to 30 vol. % – with better separation results (continuous decharging .

dog schirmer tear test

Ultimately “separator size” is an indirect reference used to define the vessel length and diameter, representing the largest size nozzle which CAN be attached to a particular separator body, NOT the actual nozzle size used to connect to your process.Nozzle centrifuge tungsten dan exalloyed di Tokopedia ∙ Promo Pengguna Baru ∙ Cicilan 0% ∙ Kurir Instan. Beli Nozzle centrifuge tungsten dan exalloyed di Sempurna Karya Mandiri. Promo khusus pengguna baru di aplikasi Tokopedia! Centrifuges are used across a wide range of industries including food processing, wastewater treatment, mining, pharmaceutical, and biofuel. So, let’s explore what centrifuge machines do, and why we depend on them to create so many of the products we use today. What happens when you turn on a centrifuge machine? There are two groups of centrifuges for liquid-solid separation: filtering centrifuges and sedimenting centrifuges. Purchas (1981) has given full account of the designs and applications of each type. . (opening bowl centrifuge), or continuously through nozzles (nozzle discharge centrifuge) . Figure 1. A disc stack centrifuge. D) The .

The Alfa Laval FESX nozzle bowl separators are designed for industrial fermentation applications and are available in many different sizes and configurations, each one designed and adapted for dealing with the widely varying separation tasks required. . The feed containing the liquid and the solids is introduced to the rotating centrifuge .Our separation technology solutions include decanter centrifuges, Tricanter®, separators, belt presses, systems & more. Made in Germany Maximum Performancethe disk-nozzle centrifuge could be used for effective waste thickening. The major problem faced by early users of the disk-nozzle centrifuge was plugging of the nozzles with grit and fiber. Im proved screening and degritting equipment have helped to eliminate this problem al most entirely. The difficult problem of waste activated sludge .

tubular bowl centrifuge diagram

Pinterest Brasil | Pinterest te ajuda encontrar as inspirações para criar a .

centrifuge nozzle|non perforated basket centrifuge diagram